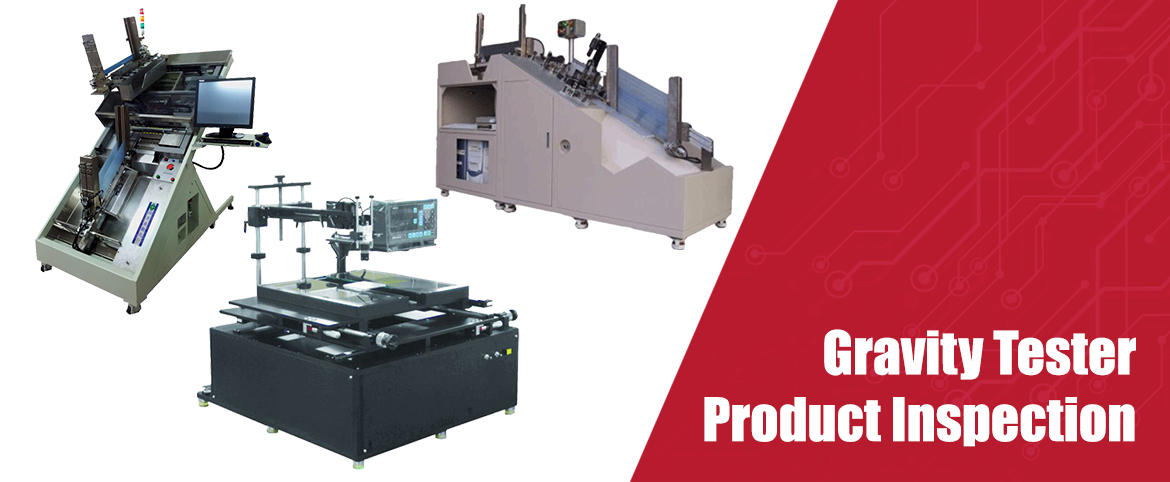

Product

Chip Right Corporation EquipmentChip Right Corporation

1.For small light-box Handler.

2.Mostly for CIS,CSP product testing.

3.Test area has 16 DUT.

4.Can place product to JEDEC Tray and Chip Tray (Waffle Tray).

5.There are two manual and two auto outputs. Eight types of engineer sorting.

6.Equipment is fast and stable with multiple safety protections.

7.Heater control is optional and AOI inspection system.

8.Friendly interface. Easy to setup and troubleshooting.

9.All kinds of statistical information are provided for analysis.

10.Support T1 Only, T2 only or T1 + T2 test in one cycle.

1.For larger light-box handler.

2.For CIS product testing.

3.Test area has Total of 16 DUT, each four form a Quadrant.

4.Input and output can be configured freely, up to six outputs. Twelve type of engineer sorting.

5.Equipment is fast and stable with multiple safety protections.

6.Friendly interface. Easy to setup and troubleshooting.

7.All kinds of statistical information are provided for analysis.

8.Support T1 Only, T2 only or T1 + T2 test in one cycle.

1.For multiple images test system.

2.Test area has total test cable. Each cable does three optical testes.

3.One set of auto input, three sets of auto output, three sets of manual output.

4.Equipment is fast and stable with multiple safety protections.

5.Friendly interface. Easy to setup and troubleshooting.

6.All kinds of statistical information are provided for analysis.

7.Support T1 Only, T2 only or T1 + T2 test in one cycle.

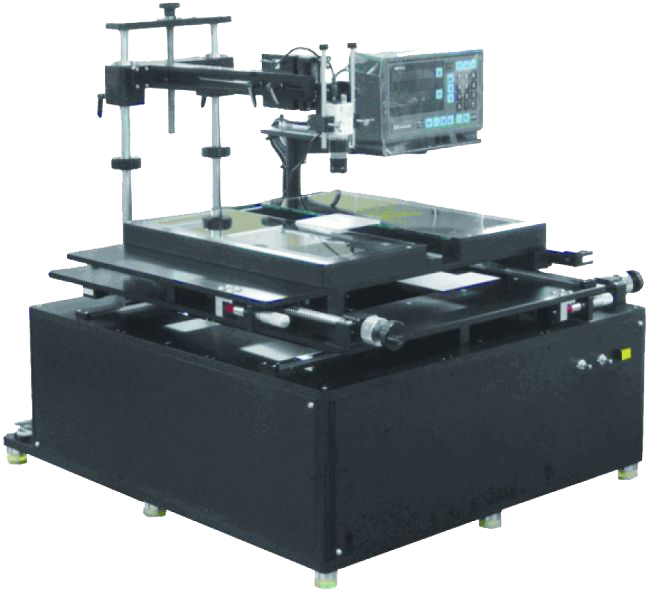

1.For manual zooming and focus testing with CIS Module Test System.

2.Test are can configured according to customers' needs.

3.Equipment is using semi auto loading and unloading, manual loading and unloading.

Equipment can automatically place product to correct position then test according to setup.

4.Friendly interface. Easy to setup and troubleshooting.

5.All kinds of statistical information are provided for analysis.

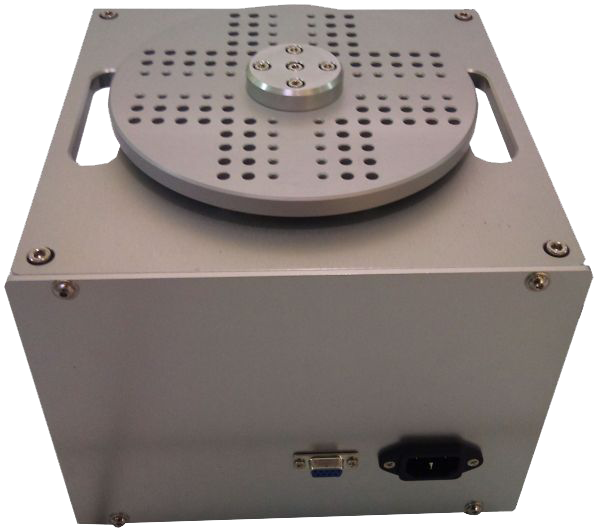

1.For testing Gyro Sensor.

2.After install sensor, swing speed, amplitude and count can be configured.

3.Friendly interface and easy to setup.

4.Can provide accurate records of speed, position and time of motion for analysis.

1.For displaying Gyro Sensor property.

2.Light weight and portable. Plug into any computer for power and usable with software installation.

3.Can provide accurate records of speed, position and time of motion for analysis and display.

4.Friendly interface and easy to setup.

1.For Flash card

2.Flash Memory or other products need longer time for testing.

3.Test area has 256 DUT, every four DUT is one set.

4.Input and output can be configured freely, up to six outputs. Twelve type of engineer sorting.

5.Equipment is fast and stable with multiple safety protections.

6.Friendly interface. Easy to setup and troubleshooting.

7.All kinds of statistical information are provided for analysis.

8.Support T1 Only, T2 only or T1 + T2 test in one cycle.

1.Can test under room temperature or high temperature.

2.For module IC test, such as ethernet chip, video chip and products need more space.

3.Test area has 6 DUT. Can test independently.

4.Three auto output, Six types of engineer sorting.

5.Using CCD to check product polarity before test.

6.Equipment is fast and stable with multiple safety protections.

7.Friendly interface. Easy to setup and troubleshooting.

8.All kinds of statistical information are provided for analysis.

1.For tubed SOP package product testing.

2.Test area has 2 DUT, can test independently, and ping pong mode.(two zones share one tester.

3.Product is directly mounted to circuit board for testing and less signal loss.

4.One auto loader, one auto un-loader, six manual un-loaders.

5.Equipment is light and handy and stable. Easy troubleshooting.

6.Friendly interface. Easy to setup and troubleshooting.

7.All kinds of statistical information are provided for analysis.

1.For tubed SOP package product testing.

2.Test area has 2 DUT, can test independently, and ping pong mode.(two zones share one tester.

3.Product is directly mounted to circuit board for testing and less signal loss.

4.One auto loader, one auto un-loader, six manual un-loaders.

5.Equipment is light and handy and stable. Easy troubleshooting.

6.Friendly interface. Easy to setup and troubleshooting.

7.All kinds of statistical information are provided for analysis.

1.For checking top and bottom kerf's width of wafer and its relation to the marking on the other side.

2.Can observe top view and bottom view immediately.

3.Can observe mix of top and bottom view.

4.Can adjust the brightness, contrast of the picture. Can enhance image appearance or detail.

5.50X optical magnification, 1-10 digital magnification.

6.Crosshair and calibration circle is provided for simplified measurement.

7.Real time image flipping for viewing needs.

8.Can save or load images.

1.For tubed DIP package products lead reforming.

2.Can change product direction before unloading.

3.One auto loader, one auto un-loader.

4.Equipment is light and handy and stable. Easy troubleshooting.

5.Friendly interface. Easy to setup and troubleshooting.

6.All kinds of statistical information are provided for analysis.

1.For testing open

2.short circuit, diode.

3.Max speed for scanning each pin is up to 0.6ms.

4.Status is check through resistance measurement.

5.Can measure from point to point.

6.Module is expandable.

7.Input current is adjustable. (0.1 mA ~ 0.3 mA)

8.Open

9.Short circuit voltage can be corrected, auto learn, and adjustable.

10.Load board are variable, or can be customized.

11.Friendly interface. Easy to setup and troubleshooting.

12.All kinds of statistical information are provided for analysis.

13.Can connect to internet. Saved test results can be printed or for reference.